1.Introduction ofcooking oil refining machine:

(1) Crude cooking oil refining workshop is through take off impurity, degumming,deacidification, decoloring, deodorization, removeing wax, fractionation etc, to achieve

different standards edible oil.

At present, Having four grade of edible oil, different oil grade have different requirement for quality and machines.

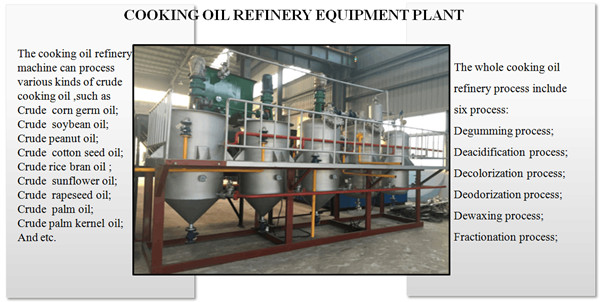

Crude cooking oil refining machine is suitable for refining various crude vegetable oil, such as sunflower oil, tea oil, groundnut oil, cottonseed oil, palm oil, rice bran oil,soybean oil, corn oil and palm oil, etc.

(2) Main parts:refining pot , decoloration pot ,deodorization pot , oil pumps and other parts

(3) Advantage: 1.After refining the impurity of oil must be less than 0.2% ;

2.Recycling system save power and money ;

3.Lower oil waste.

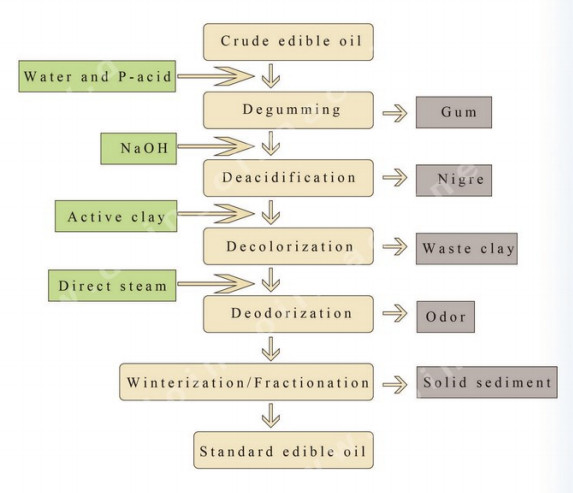

Main oil refining steps of cooking oil refining machine:

1. Degumming: Removing the phosphatide by adding hot water, when phosphatide meets hot water, it will become bigger and bigger, then out of tanks.

2. Deacidification: Removing the FFA by add alkali liquor (for taking neutralization reaction).

3. Decolorization(Bleaching): Remove the pigment by adding bleaching earth( it has strong adsorption of pigment), and the remaining bleaching earth will be filtrated by leaf filter.

4. Deodorization: Remove the oxide, solid particle and volatile gas.

5. Waxiness impacts palatability of oil; winterization/dewaxing focuses on increasing palatability of oil and impoving organoleptic properties such as transparency, brightness, etc. Waxiness content of different oils varies; winterization/dewaxing is necessary to oils like corn oil, sunflower seed oil, cotton seed oil, etc.

In general, freezing crystallization is widely used in winterization/dewaxing. In another word, reduce oil temperature and crystallize waxiness at first, and separate solid waxiness from liquid oil mechanically.

2.Working process of cooking oil refining machine:

(1)Pump crude edible oil into refining tank and heat with conduction oil, and the temperature will reach about 70°C-80°C after one hour.Add acid or alkali to separate

according to the acid value. After one hour's processing and 4-6hours deposit, then convey soap stock to storage tank.

Contact information:

Skype:sophia.zang1

Mobile:+86 13526627860

Phone:+86-371-5677 1823

Website:www.doingoilmachine.com

E-mail: oilmachine@doingoilmachine.com