|

Henan Doing Mechanical Equipment Co,Ltd. Is a professional manufacturer of cooking oil machine , We have been in cooking oil machine manufactuering industry for 40 years.With rich experiences, our engineer team helps customers design different cooking oil machine with different capacities .

Company information :

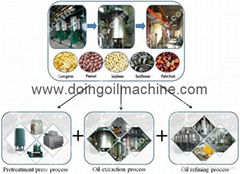

Doing Group have the whole line of oilseeds pretreatment and pressing plant, solvent extraction line and oil refinery plant.

The processing capacity is as below:

10-2000 T/D oilseeds prepress line and pretreatment line

20-2000 T/D Automatic and complete rotocel extractor and loop type extractor

2-1000 T/D Animal fat, oil fat, used cooking oil/PAD/PFAD to biodiesel production line

Doing Group has more than 40 years experience on oil machinery, turnkey project service will be provided to customers.

Doing Group have installed hundreds of plant all over the world, our responsible engineers, advanced tech and experienced installation worker will make your choice better and better.

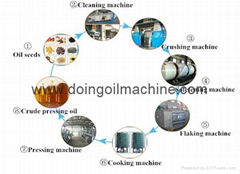

Cooking oil pretreatment /press machine

Cooking oil press machine is made up of oil seeds cleaning machine,oil seeds crushing machine,oil seeds softening machine,oil seeds flaking machine,oil seeds pressing machine and cooking oil filter machine.

Oil extraction machine

Oil extraction machine is mainly use to extract cooking oil from various kinds of oi seeds.such as corn germ ,peanut ,soybean ,cottonseed,rice bran and palm kernel .

Cooking oil refining machine

Crude oil obtained from expellers or solvent extraction, contains impurities. To make the oil edible, the impurities must be taken out; such a process is called “oil refining(oil refinery plant)”. Oil Refining (Oil Refinery Plant) means conversion from crude oil to direct human consumption, crude oil refinery, edible oil refinery, oil refinery projects and industrial purpose.

Palm oil processing machine

Palm oil mill process is quite diffferent from other oil seeds processing, such as the soybean , peanut etc. Palm fruits consists a lot of fatty acid enzyme, which would hydrolyze palm oil. That's the reason why palm fruit must be sent into processing in 24 hours.

Palm oil mill process includes 6 parts: Palm bunches receiving, sterilizer, threshing, mashing and pressing, crude oil clarifying and palm kernel recovery.

Palm oil mill process includes 6 parts: Palm bunches receiving, sterilizer, threshing, mashing and pressing, crude oil clarifying and palm kernel recovery.

- See more at: http://www.palmoilextractionmachine.com/product/palm_oil_press_machine/palm_oil_mill_85.html#sthash.pNZxsJvP.dpuf